PUMPING UNITS

- Known the world over for their superior ability to tackle large projects with heavy-lift requirements, PumpJack Supply’s Pumping units are engineered and manufactured with the highest quality materials available.

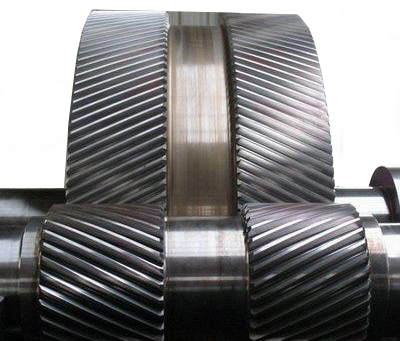

- Our complete line of models is manufactured to API standards in gear reducer sizes ranging from 40’s to 1824’s. They come in conventional and beam balanced models. Each model makes it possible for producers to complete the most challenging lifting requirements. To help ensure optimum performance, Pumpjack Supply can assist with the design of an efficient rod pumping system.

- The history of the design of our pumpjack has been in the US and around the world for over 50 years. There are over 20,000 units in the US and another 30,000 worldwide.

- Using the best engineering designs, specifications and factories, we are bringing this product into Canada under the PJS label.